Slate tiles

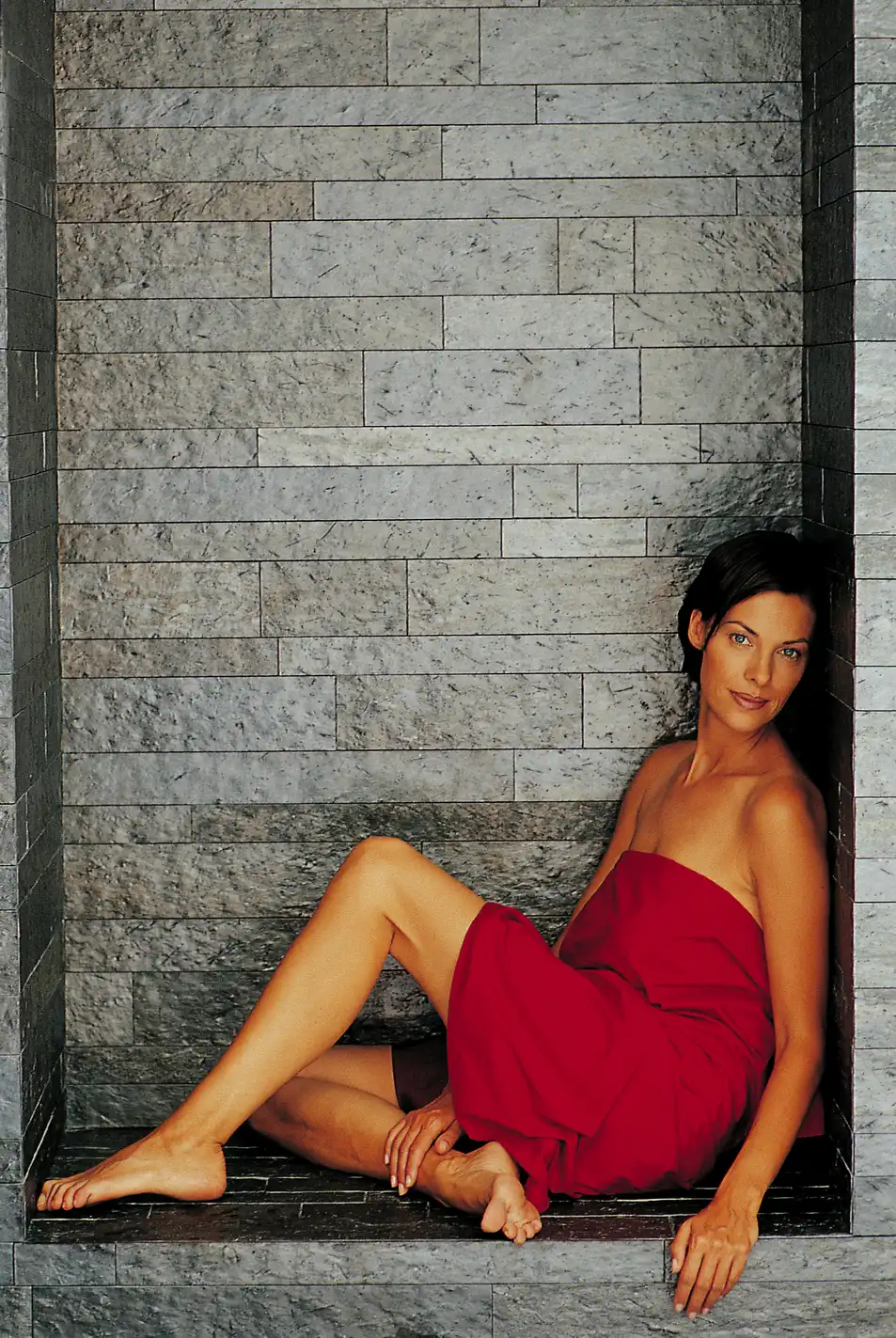

Slate tiles are the common term for thin slate with a smooth and fine natural surface.

Slate tiles are as versatile as other types of tiles, and are perfectly suited for use on both floors and walls. Our slate is frost-resistant. This also makes it ideal for use outdoors, such as on stairs, paving, terraces, etc. Each individual stone has its own unique expression and you will never find two stones that are exactly alike. This gives each project an exclusive and distinct feel.

Products

OTTA Rust

Otta Rust is only supplied in natural surfaces. The reason for this is that the distinct rust color disappears as soon as the slate is processed.

Natural surface, in thicknesses: 8–17 mm, 18–25 mm, 10 mm, 15 mm and 18 mm. Widths 200, 300, 400 mm x fl, 300×600, 400×600, 300×300, 400×400 mm.

OTTA black, standard

Natural surface, in thicknesses: 8–17 mm, 18–25 mm, 10 mm, 15 mm and 18 mm. Widths 200, 300, 400 mm x fl, 300×600, 400×600, 300×300, 400×400 mm.

Brushed surface, in thicknesses: 8 mm Widths: 200, 300, 400 mm x fl, 300×600, 400×600, 300×300, 400×400 mm

Sanded surface, in thicknesses, 10 mm. Widths, 200, 300, 400 mm x fl, 300×600, 400×600, 300×300, 400×400 mm

We also supply other desired measurements and thicknesses on request.

Thickness interval on slate tiles

The tiles are offered in specific thickness intervals such as 8 mm, 10 mm, 8-17 mm etc. See full overview in the product tab. The intervals indicate the variation in thickness between individual shale slabs within the specified grading. Although each individual tile is generally uniform in thickness, small irregularities may occur.

To attach the slate directly to the substrate, the use of slate glue/mortar glue is recommended. The height of the substrate need not be significant to compensate for the variation in thickness of the tiles. Minor irregularities are easily corrected by applying the right amount of glue.

If slate tiles are to be laid outdoors, foundation work is essential. Consideration must be given to efficient and good drainage of moisture to avoid uneven moisture exposure from the underside. This is particularly important to prevent spots or shields on the surface.

It is recommended to follow the manufacturer’s recommendations for the correct installation of slate when using glue. The various glue manufacturers provide detailed descriptions that ensure a safe and efficient installation.

Slate tiles with adjusted thickness

We also produce slate tiles with customized thickness. The back side is diamond milled down to a specified thickness. The adjusted thickness enables faster installation. The tiles are installed directly on the substrate using tile adhesive designed for natural stone.

It is recommended to follow the adhesive manufacturer’s guidelines for the correct installation of slate when using adhesive. The various manufacturers provide detailed descriptions that ensure a safe and efficient installation.

Use of slate tiles outside

The Otta slate can, in the same way as all other dark materials such as e.g. ceramic tile, get very hot in the sun. The slate will thus be exposed to large temperature fluctuations throughout the day. This presents greater challenges in relation to lasting adhesion properties.

It is recommended to follow the adhesive manufacturer’s guidelines for the correct installation of slate when using adhesive. The various manufacturers provide detailed descriptions that ensure a safe and efficient installation.

OTTA outdoor tile

Natural

Brushed outdoor tile with thickness 25 mm and width 20 x falling.

Coating slabs with thickness 25–40, 40-60, 60-80 mm and width 200, 300, 400 mm x falling.

We also supply other desired measurements and thicknesses on request.

Format: width and length

Ottaskifer is produced in standard widths and varying lengths (referred to as falling lengths). This provides the best possible safeguarding of the natural resource at the same time as it provides a beautiful and “living” surface.

We also produce rectangular- and square slate, to the customer’s wishes.

Strips

Strips are very narrow tiles that are delivered in falling lengths. These are delivered individually, and you can mix the three different standards yourself to create your own unique design. Strips are also supplied in adjusted thickness, which gives a tighter and more precise expression. Strips can be used on both floors and walls in the same areas of use as slate tiles. Skirting/flooring in the same material as the floor itself adds the finishing touch.

OTTA Strips

Naturoverflate

Tykkelser: 10 mm Bredder 30, 50, 80 mm x fallende.

Brushed surface

Thickness: 8 mm Width 30, 50, 80 mm x falling

Antique brushed surface

The natural surface of the slate is processed through an antique brush process. This process results in a wear that gives the slate an antique patina. The resulting surface is glossy and easy to care for. Even with this treatment, the slate preserves the natural structure with small irregularities, which act as an authentic signature.

Brushed surface

The natural surface of the slate is milled and brushed. This results in a smooth, glossy surface. The brushed surface differs from a sanded surface with its natural pores that are still visible, and a natural structure that can be felt. The play of colors comes across more clearly, and the silk-brushed surface is hardened and dense, which makes it extra easy to wash and care for.

The characteristic feature of Ottaskifer makes the robust hornblende/needles in the surface appear even more clearly, creating a three-dimensional effect. This results in a surface with extra character and ease of maintenance.

Deep brushed surface

With extra hard pressure during brushing, the needles are further accentuated, providing even better anti-slip protection. This is particularly suitable for outdoor use.

Sanded surface

The surface is ground with diamond tools through several grinding heads. This creates a completely smooth surface with a distinctive three-dimensional effect. The needles are ground down to a smooth finish and the surface is completely smooth without any traces of natural structure. This gives it an exclusive character.